In principle, the state of the art today distinguishes between two methods for measuring the particle content of the air:

the gravimetric and optical methods.

Gravimetric particle measurement is based on a very fine filter fabric through which a precisely defined air flow is drawn by a pump over a defined period of time.

The dust particles remain trapped in the filter fabric. After collection, the filter is dried, weighed and the dust concentration is calculated based on the air volume and time.

In the optical method, the concentration of dust in the air is calculated on the basis of light scattering and complicated algorithms.

This can be vividly compared, for example, with the sun's rays of light shining through a window into a dusty room on a fine day. You can see the individual rays of sunlight through the dust, which is the reflection of the sunlight that the dust particles reflect back into the room. The main advantage of this method is the continuous measurement and immediate display, which eliminates the need for laboratory evaluation, as is the case with gravimetric measurement.

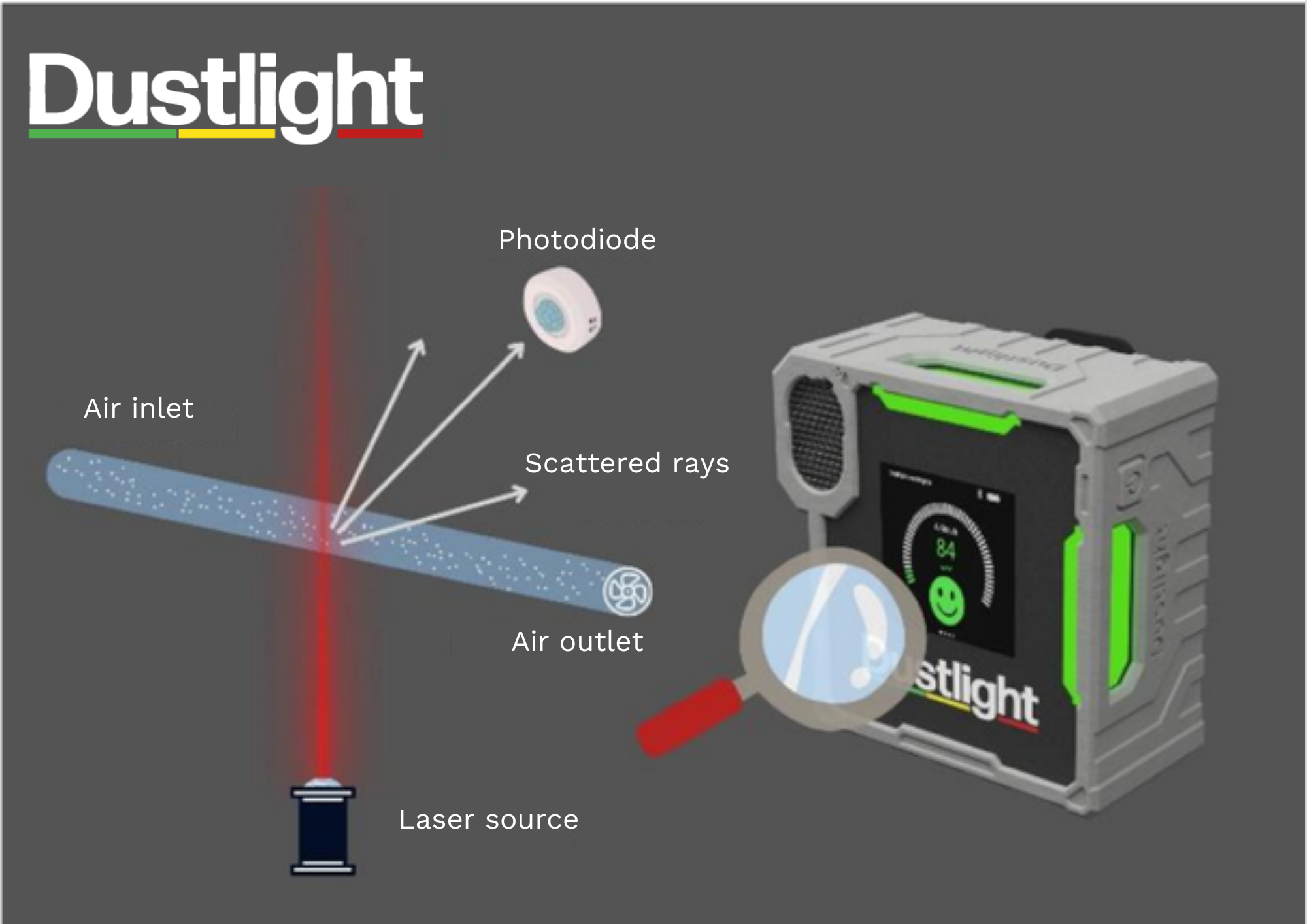

Our measuring principle

Dustlight is based on the second, optical measuring method. However, to enable the compact design of the Dustlight, we use a small, powerful laser diode and a photodiode that can detect the backscattered light. The laser diode emits light beams through the aspirated air. The particles in the air scatter some of the light, which the photodiode captures and converts into electrical signals. A fan inside the device ensures a constant airflow so that the Dustlight can always measure the actual dust concentration in the environment and react to changes within seconds.

The algorithm that converts the measured signal into a mass concentration is a unique feature of the Dustlight. The reason for this is that the optical parameters of the particles (such as the refractive index and shape) have a major influence on the estimation of the particle mass. Therefore, the indirect optical (laser-based) measurement always has a discrepancy compared to the more accurate direct gravimetric (weight-based) methods. Our technology has been calibrated in extensive tests with different types of dust to ensure the highest accuracy.

Our algorithm

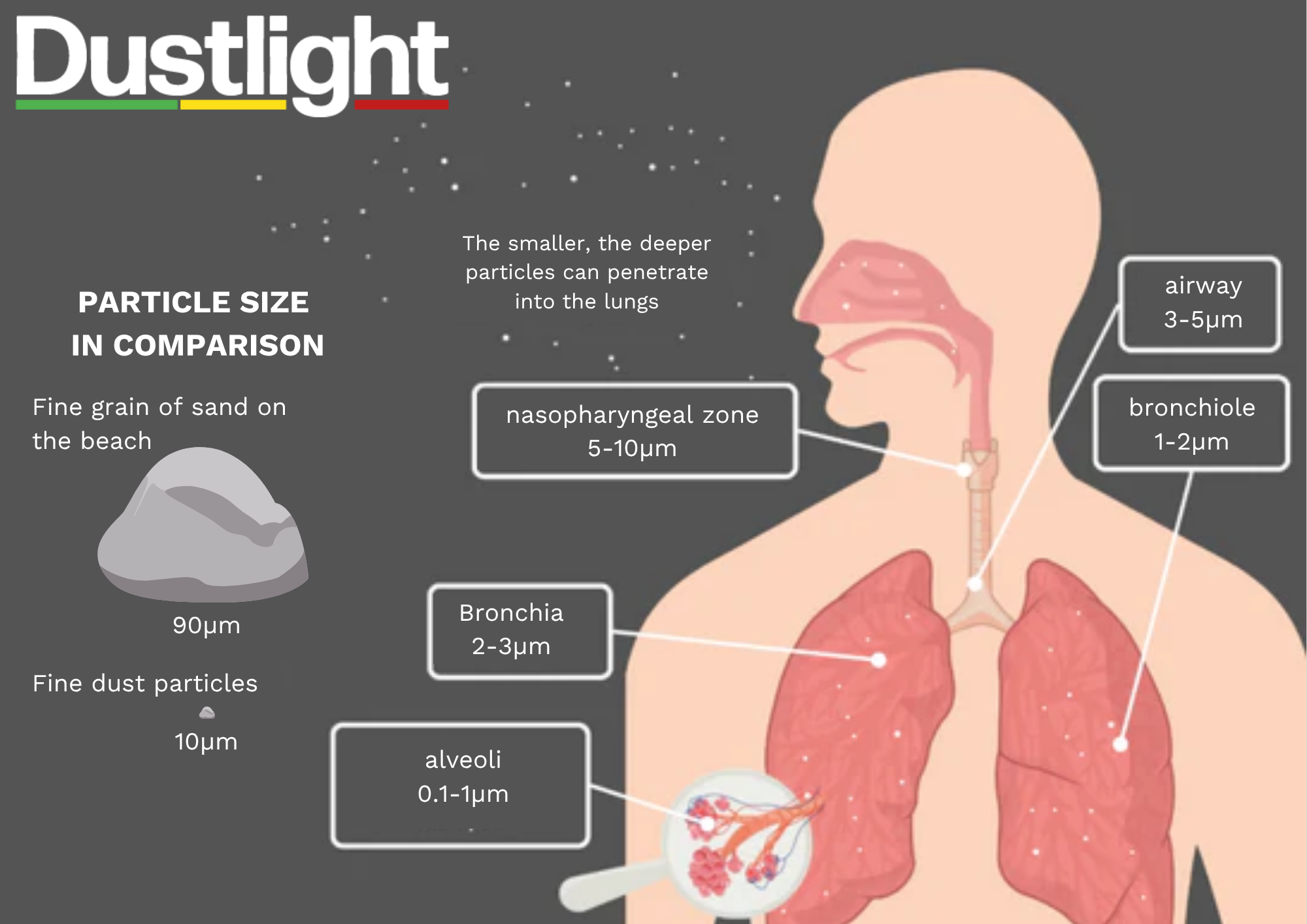

The fine dust size that is particularly relevant in occupational safety and therefore for the display on the Dustlight is respirable dust, or A-dust for short. This is so small that it can penetrate into the finest branches of the lungs, the alveoli, when inhaled. Due to their small size, A-dust particles can reach this area and develop their harmful effects there. The size of these particles is a size distribution with a decreasing probability of penetrating into the alveoli the larger the particles become.

We reproduce this size distribution with our algorithm so that our displayed measured values correspond as closely as possible to the particles in the air that can actually penetrate the lungs. To achieve this, we have spent many hours testing in Germany's leading dust measurement laboratories, which has enabled us to further optimize the measurement accuracy in several iterations. Further information on dust and occupational exposure limits can be found in our white paper, further information on measurement accuracy can be found in the data sheet.

Our protection concept

We have developed the Dustlight for harsh environments such as in industry, mining or on construction sites, where it will be exposed to dust, dirt and mechanical impacts such as shocks and vibrations. To ensure the function and reliability of our sensor technology, we have developed a comprehensive protection concept and applied for a patent.

- Mechanical: First, the intake air is cleaned of coarse particles via a close-meshed grille. This grille can be removed for easy cleaning and can also be easily replaced. The air then flows through our settling chamber, in which larger particles that were able to pass through the grid but are not relevant for the measurement settle.

- Veiling air: After mechanical pre-filtering, the air flow is divided into two parts, one of which is cleaned by a filter and passed as veiling air between the "dirty" ambient air flow and the photodiode. This effectively prevents dirt particles from being deposited on the optics of our sensors.

- Self-cleaning: The device's self-cleaning function is activated automatically at certain intervals. This significantly increases the fan speed so that any deposited dust particles are loosened and cannot affect the measurement if they come loose on their own during operation.

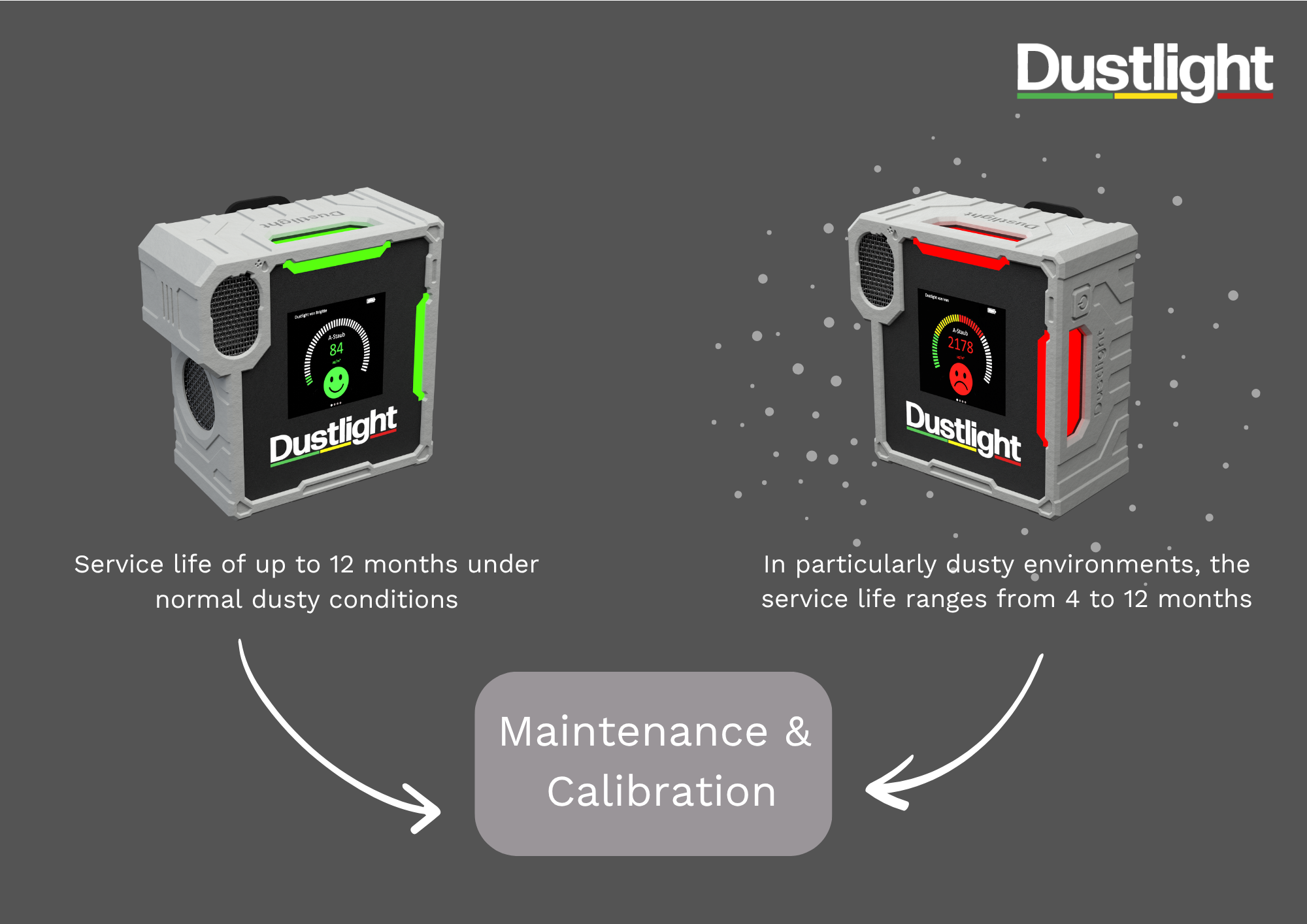

Our maintenance concept

As with any other measuring device, it is important to be able to rely on the displayed measured values at all times. To this end, the device must be cleaned at regular intervals and tested and recalibrated against a reference measuring device under controlled conditions.

Thanks to our extensive testing, we have been able to simulate the intervals at which such maintenance is required very well depending on the actual dust load. Each Dustlight therefore has an intelligent maintenance calculation that calculates the optimum intervals based on the operating conditions. However, the first maintenance must be carried out after 12 months at the latest, as ageing and daily use in harsh environments can also have an impact on measurement accuracy.

The current status can be viewed at any time in the Dustlight app, and the device also issues a notification as soon as 80% of the time has been reached and a warning when the recommended maintenance interval is reached. The app provides all the information required to carry out the maintenance and this can be booked directly via the app and our website.

Here you can find all our products at a glance.